When most people think of Hiroshima, they picture the Atomic Bomb Dome or the isle of Miyajima with its floating tori and plentiful deer. However, after 2018’s July rain disaster, many people’s minds turned to the floods and landslides caused by the extreme downpours. But, Hiroshima is nothing if not resilient. The city — and the prefecture as a whole — is no stranger to hardship, nor to rising from the rubble and striving to be better than before. Nine months on and the region is back on track and full of promise. One of the many initiatives giving businesses a boost in the right direction is the Hiroshima Sandbox Project.

The Hiroshima Sandbox Project — Fostering Innovation for a New Generation

While Hiroshima may not be an obvious pick for one of Japan’s innovative prefectures, the region has a long history of being a heavy manufacturing hub and is currently one of the largest growing economies in Japan. Household names like Daiso, Calbee, suit store chain Aoyama and Mazda all originally hail from here, and there are many more businesses who have successfully become the best — or the only ones — in their industry. To give them an extra helping hand, Hiroshima prefecture has started many projects, including The Sandbox Project, an initiative to foster innovation, especially in IoT (Internet of Things) and AI (Artificial Intelligence).

The government has set aside ¥1 billion to be dispersed over three years, to several eligible companies and projects. They will also offer assistance in connecting companies and groups to achieve their goals. The idea is to create an environment where ideas are free to be experimented with and without the fear of failure. By providing a support network for businesses to explore new methods and technologies, it will help them innovate and excel in their fields. Hiroshima hopes to be at the forefront of innovation as it tackles current and future issues such as climate change, aging populations, natural disasters and more. Here’s a closer look at some of the companies planning to change challenges into opportunities.

Asukanet — The Realm of Science Fiction Reaches Real Life

Asukanet Co., Ltd started out in 1995 providing photo editing for funeral services but is now first in the world with technology straight out of a science fiction film. The ASKA3D-plate projects videos, images and objects in midair. While this may seem like a simple hologram, here’s the kicker — you can interact with the images, meaning you can use a touch panel without actually coming into physical contact with a device. The technology is still new, but the applications are limitless: surgeons would be able to confirm data without taking their gloves off or contaminating hardware mid-surgery, office workers could do desk work without a physical computer in front of them, it could even revolutionize digital advertising and entertainment as we know it. Asukanet’s products have been used in BMW’s concept cars and with mass production of the ASKA3D-plate becoming a reality, it’s only a matter of time before this space-age technology is at our fingertips.

https://www.youtube.com/watch?v=M_FSOGrSwOY&feature=youtu.be

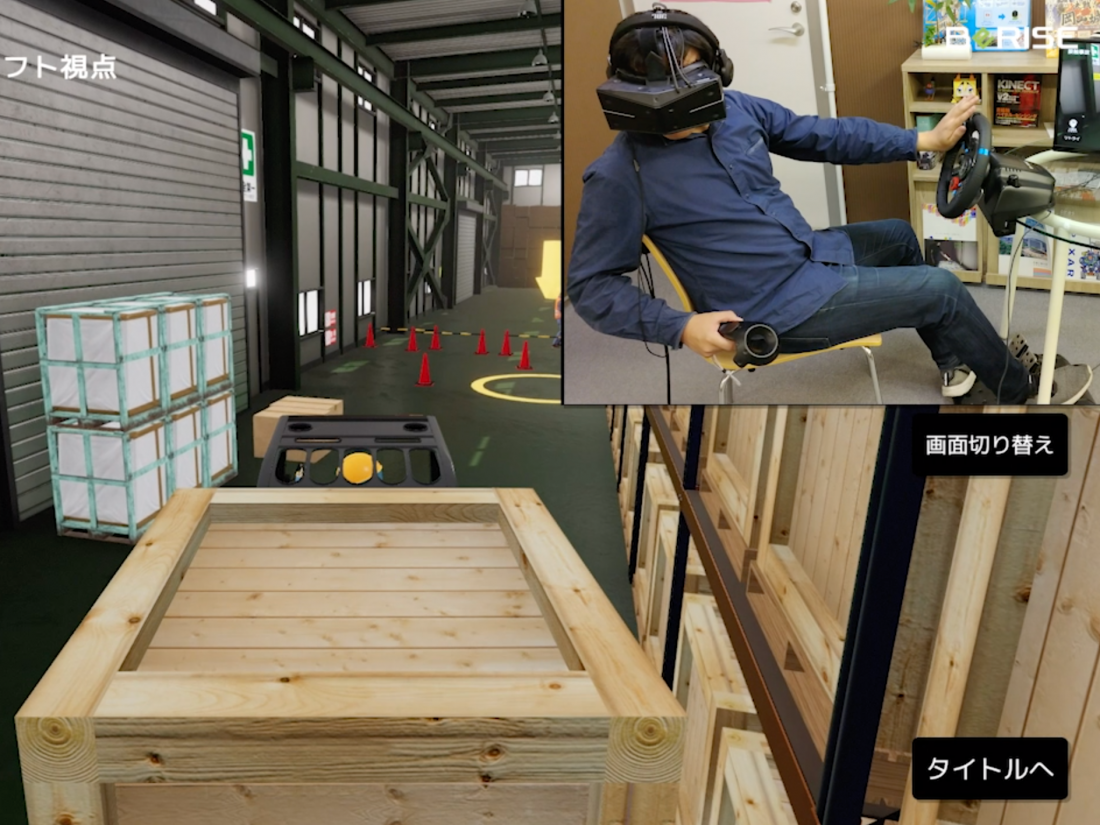

BeRISE Inc. — Making the Workplace Safer through Virtual Reality

While many businesses have pushed virtual reality as a form of entertainment, BeRISE Inc. focuses on educational programs. By forming high-quality virtual worlds, BeRISE can create realistic experiences that help users close the gap between theoretical and practical knowledge. Safety education, in particular, appears to be effective as users can experience real-life situations without potentially dangerous consequences. For example, construction workers can navigate a simulation of a high-altitude work site without a safety belt (and fall when hit by a beam), electricians can practice working with switchboards without getting electrocuted, and forklift drivers are reminded of blind spots. There is an increasing number of scenarios in the works for the future, including disaster preparation, medical education and nursing care.

Lemon and Oyster Farming – IoT and The Future of Food

With an increasingly aging population, climate change, and fewer farmers and fishermen in the region, two of Hiroshima’s most famous exports — lemons and oysters — are in danger. However, these challenges are potential opportunities, and with the help of IoT and support from the Sandbox Project, the future is looking brighter.

Lemon farming started on the Tobishima islands in Hiroshima prefecture about 20 years ago and was the first place to domestically produce the fruit. Hiroshima is still the nation’s largest supplier of lemons, though it only supplies about 10 percent of the demand. Together with local farmers, the cooperative The Tobishima Citrus Club collectively produces lemon-based products including marmalades, meringues and even shampoo!

The group is working with Enecom to digitalize lemon farms, using sensors to pick up data and conditions such as temperature and humidity, while drones update with images and monitor any changes. By combining the data with farmers’ know-how, it will make it easier for existing farmers to increase production and for newcomers to get into the industry. There are also plans in motion to make use of robots to carry baskets full of lemons — which can weigh up to 20 kilograms — down the steep slopes of the orchards.

As for Hiroshima’s marine mollusks, Etajima (the second largest oyster-producing area in Japan) has plans to use ICT (Information and Communications Technology) in collaboration with SHARP and University of Tokyo’s Akihiro Nakao, professor of applied computer science. Climate change has already begun to affect the spawning habits of oysters — baby oysters must be caught within a two-week period to be harvested for future farming, but the spawning period can be unpredictable. By monitoring the oyster rafts with drones, measuring water temperature, salt density and temperature, oyster farmers can see changes in real time and adjust accordingly. It can even allow them to prepare for potential disasters in advance. Sensors use solar panels and batteries and are low-cost, energy efficient methods to detect changes in real time, which will eventually be done by a smartphone app. This project is still in its early days — it started in December 2018 — but project members have high hopes it will help oyster farmers mitigate the effects of any challenges they are facing.

Luce Search — Surveying Land and Saving Lives

While not financed by the Sandbox Project, Luce Search has received assistance from a national government initiative, the Regulatory Sandbox system/National Strategic Special Zones. The system deregulates some laws and roles in certain areas — Hiroshima included — so that businesses can experiment in relevant fields.

Luce Search designs and manufactures drones for photography, bridge inspections, weather surveying and land mapping. Most recently, the company has forayed into disaster survey. The latest Spider-NE model can fly at speeds up to 72 kilometers an hour and has a max flight time of three hours, greatly increasing the drone’s capability. An analysis of the data collected can be completed in 30 minutes, saving time, energy and money. As an example, it takes two weeks for people to manually survey a 3km² stretch of land for any cracks (which would indicate risk for landslides). For Luce Search’s drone, it takes two days to cover the same area — potentially saving thousands of lives. The drones also offer an overview of damages after a disaster, making it easier to assess what hard-to-reach areas are most severely affected.

With these — and many more — Hiroshima businesses creating innovative ways to deal with ever-increasing economic competition and challenging climates, the future looks a little less dark.

[Sponsored Post]