This article appeared in Made in Japan Vol. 4.

To read the entire issue, click here.

Japan is world-famous for experimental fashion. From Issey Miyake’s pleats to Rei Kawakubo’s lumps and bumps, the Japanese avant-garde silhouette shot to fame as the country’s approach towards bold and innovative clothing in the 1990s. Fast-forward to the present, and designers are spearheading a new wave of experimentation, this time with a focus on materials. While the global fashion industry is notorious for its environmental impact — it currently stands as the world’s third-largest polluter — Japan’s fashion innovators are increasingly turning to experimental, natural materials for future-friendly style solutions.

Here are four picks that showcase the weird and wonderful, in a mix of tradition and technology.

Cloth made from Curetex’s washi-based material

Curetex: Cloth Made From Paper

While paper may not seem an obvious choice for clothing, it could be something we’ll see more of in the future. Several new paper-based materials have been developed in Japan recently, and one example is Curetex, a fine yarn made from 100% Japanese washi, from the manufacturing company Cure Group Ltd. The current range of paper-textile items includes socks, neckties, handkerchiefs and bags. Surprisingly, washi boasts numerous benefits when applied to wearables: It’s breathable, moisture-wicking, deodorizing and UV protective.

Washi paper has a rich history in Japanese culture, including within clothing; the long fibers it’s made from allow it to be strong and versatile, and, fashion-wise, it was used for everything from undergarments to hair accessories until the Meiji era. Curetex’s manufacture resembles a paper yarn used during this time known as shifu. Made by cutting paper into strips and tightly twisting it, shifu is strong and durable. However, the technology within Curetex’s current processing transforms washi yarn into a much finer contemporary material, with wider uses and future potential.

For more information on Curetex, visit their website.

9-jour: Denim Dyed With Flowers

The cool and earth-friendly jeans from Tokyo-based brand 9-jour are looking to the past to inform the future by using a new dyeing technique called shin-manyozome.

Initially developed by researchers at Mie University, shin-manyozome is based on the vibrant colors in traditional kimono that were achieved before the introduction of synthetic dyes. The process combines ancient knowledge with a contemporary goal of eco-friendliness; less pigment and no chemical fixatives are needed, yet the colors produced are vibrant and lustrous. More impressively, the technique uses only plant-based materials.

In adopting this dyeing method, 9-jour has experimented with various flower/plant combinations, resulting in a bright and brilliant color range that takes selvage denim to the next level. 9-jour’s philosophy is a breath of fresh air at a time when chemical dyes are polluting the world’s waterways: The brand claims that no harmful waste or water pollution is created during the manufacturing process, and their fair-trade denim jeans are designed in classic gender-neutral cuts, intended to stand the test of time.

Customers can scope out and pre-order their preferred color in 9-jour’s Omotesando showroom. Dyeing and production take place in small batches throughout the year, according to the seasons.

Check out 9-jour’s colorful wares on their website.

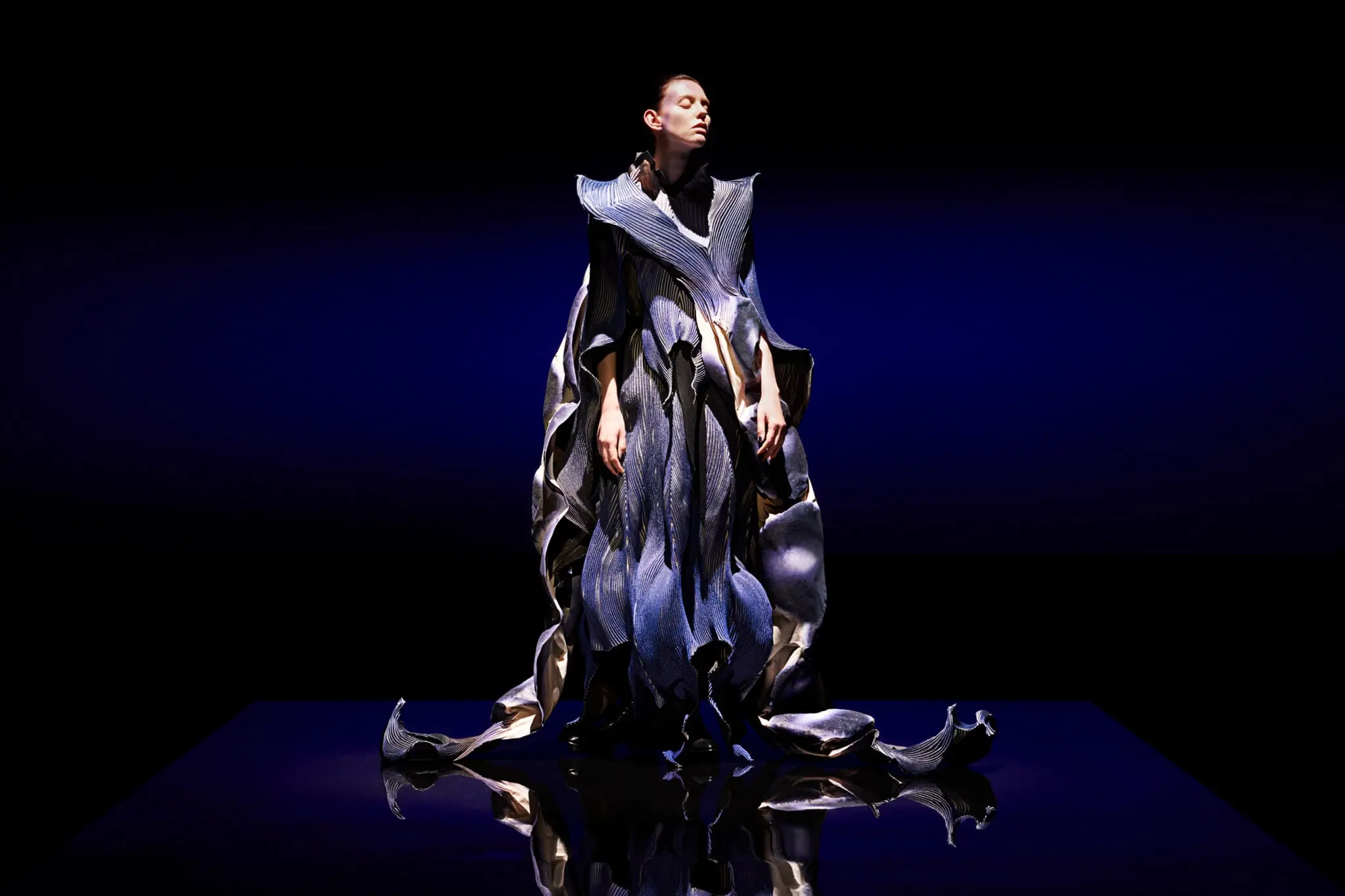

© Yuima Nakazato

Yuima Nakazato: Architectural All-Natural Textiles

Designer Yuima Nakazato’s “biosmocking” material is a feat of creativity, first unveiled through a series of sculptural designs in his AW 21/22 collection. A term coined by Nakazato, biosmocking involves combining traditional textiles, such as the Kyoto kimono fabric Nishijin-ori, with a new plant-based fiber developed by the Japanese company Spiber. The resulting fibers can replicate natural materials like wool and cashmere, yet require 97% less water and 99% less land during production when compared with their animal-based equivalents.

The biosmocking fabric is printed with UV reactive inks, and contracts into deep rigid grooves and rich kaleidoscopic colors when exposed to light. Nakazato’s experimentation with mixing fibers and techniques is ongoing — for AW 22/23 he applied traditional Japanese lacquer to some of his garments — and he continues to push the boundaries of what can be achievable in textile design by combining technology with tradition.

To see more of Nakazato’s beautiful creations, visit his website.

Ovoveil: Silk Made From Eggshells

Redefining what we may think of as futuristic, “Ovoveil” is a new, silk-like material made from eggshell membrane, produced by the Kyoto-based company Pharma Foods. Ovoveil made its fashion debut this year at New York Fashion Week in the form of printed “silk” capes, in the AW 24/25 show from upcoming brand Sound Of Ikebana by Naoko Tosa.

A reported 2.63 million tons of chicken eggs are used in Japan each year, creating 260,000 tons of eggshell waste. Recognizing this, Pharma Foods set about to consider the further possible uses for eggshells, leading to the company’s discovery that the thin, internal membrane layer of an egg contains antibacterial and UV protective properties when made into a fiber. Ovoveil is described as having a “slippery” and silk-like feel, and in recent testing, it has been shown to improve the skin’s moisture barrier after prolonged wear.

With FSC-certified sustainability credentials and significantly cheaper production costs than silk, this bio-material shows that sustainability needn’t come at the sacrifice of comfort or luxury.

Learn more about Ovoveil’s creation process on the Pharma Foods website.