This article appeared in Made in Japan Vol. 4.

To read the entire issue, click here.

At first glance, it may seem like an unexpected pairing: a tiny farm of Japanese craftsmen practicing traditional dyeing techniques, and Arc’teryx, a global brand known for its sleek, hi-tech climbing gear. But Kakuo Kaji, the blue-nailed founder of Buaisou (stylized as BUAISOU) is accustomed to high-fashion and modern collaborations.

Buaisou, based in Tokushima, is the first farm-to-closet dyer in Japan, specializing in denim, clothes and artwork. In the past, they’ve worked alongside international brands like Jimmy Choo, Uniqlo and Kith to create pieces that showcase the versatility and ingenuity of indigo dyeing. (Rihanna has visited their workshop, too.) The Arc’teryx piece is their most recent big-name partnership, and their most ambitious — a 4.8-meter-wide and 1.2-meter-high custom panel for the brand’s recently opened Tokyo Creation Center in Daikanyama.

Photos by Kyoko Nishimoto, BUAISOU

A deep indigo blue, subtly graduated from bottom to top, the artwork is emblazoned with an intricate rope design, twisting and winding its way up the panel. In our interview, good-humored Kaji downplays the effort it took. But his manager Kyoko Nishimoto interjects: After three failed attempts, Kaji worked from 8:30 a.m. to 4 a.m. for two weeks to finish the piece on time, stenciling, pasting and dyeing. The final piece was completed on very little sleep and a lot of adrenalin.

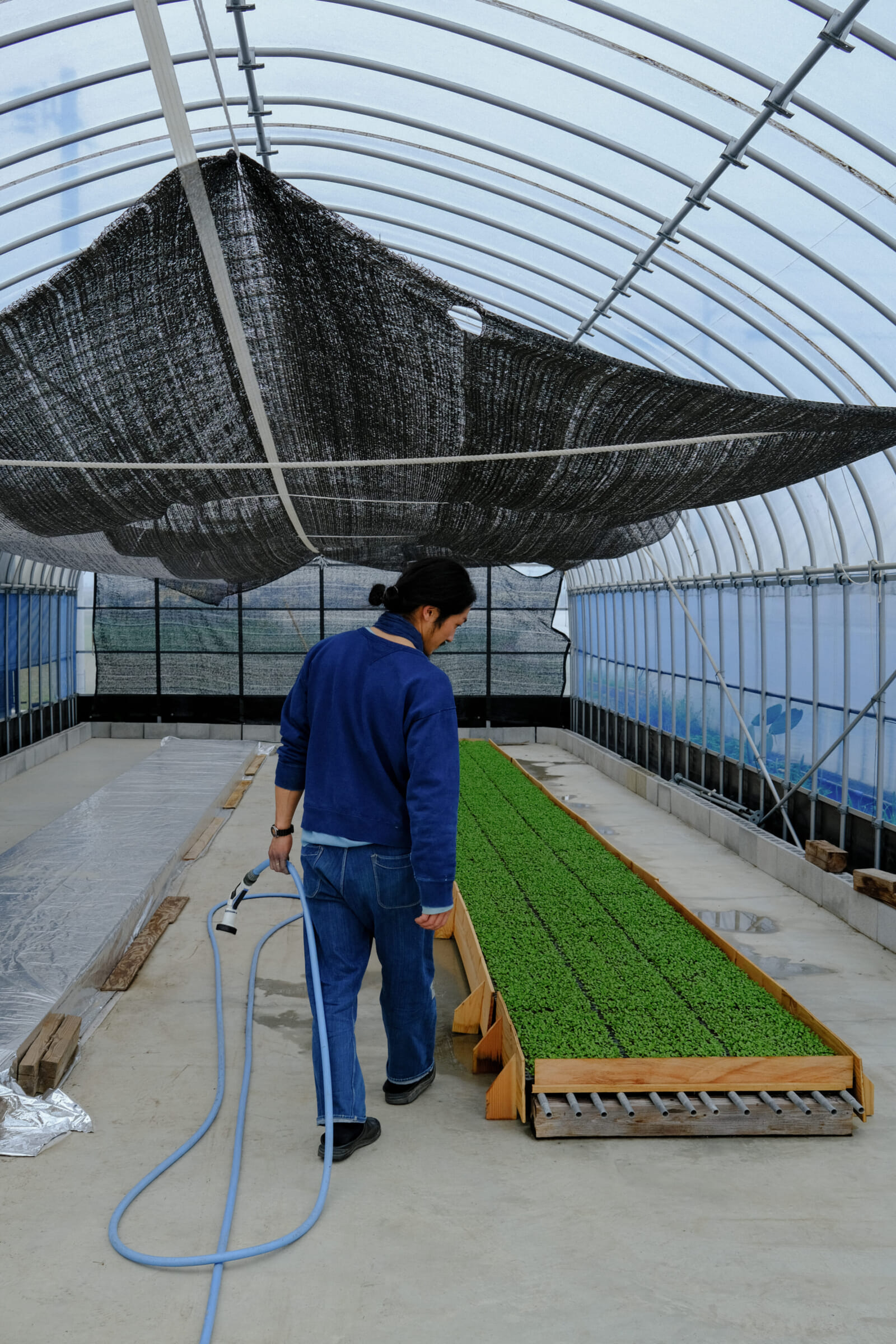

From Seed to Garment

Kaji was originally keen on fashion and dyeing separately, until he realized he could combine the two. “I discovered that in the past, Levi’s used natural dye to color their jeans, which put me onto dyeing denim itself,” he explains. Originally from Aomori, he relocated to Kamiita town in Tokushima Prefecture in 2012, after applying to the Chiiki Okoshi Tai, a government scheme which provides young people with funding to move to the countryside.

“There were only two of us who applied,” he says. “I figured that if it didn’t work out, I could just move back to Tokyo.” Work out it did, and in 2015, Kaji registered Buaisou as a company which hand-dyes indigo products using indigo they’ve grown themselves. Now, there are six members of the Buaisou team, including Nishimoto, who works as their communication department and manager.

Typically, dyers and indigo makers work separately: Clothing brands which specialize in indigo products will purchase dye from a dye-maker, who creates the indigo either synthetically or from the plant. Buaisou, conversely, does everything on-site. They have their own indigo field, where they cultivate the plant from seed, then ferment its leaves into the liquid for dyeing, known as eki in Japanese. They dye all their pieces by hand, be that artwork or clothing; they’re best known for their denim and the instructional workshops they host about the traditional art they practice.

Photo by Brad Holdgrafer

Devotion to Craft

On the night of the opening, I head over to the Arc’teryx Tokyo Creation Center with Kaji and Nishimoto, who are both dressed in what seems to be an unofficial uniform: blue from top to bottom. Kaji’s signature azure fingernails aren’t meant as a fashion statement — they’re permanently tinged from working with indigo every day. His hands are remarkably stain-free, as he admits that he’s freshly scrubbed for the occasion. It’s a big day for Buaisou. This event will mark the unveiling of their artwork in all its glory.

To make the piece, Buasiou used katazome, a technique similar to the more commonly-known batik dyeing from Indonesia. While batik uses wax to dye fabulous patterns into cloth, the katazome method uses a glue-like rice bran paste to mark out which parts will stay clear from the dye. First, a stencil is cut, then the paste is applied and left to dry before the whole fabric is soaked in the indigo dyeing liquid, over and over again to ensure deep color.

Photos by Kyoko Nishimoto, BUAISOU

When deciding upon the image that will adorn the panel, the team considered Arc’teryx’s origins as a maker of climbing equipment — rope in particular. The Buaisou artworks are known for depicting rope and yarn through katazome stenciling, so it was a case of building upon what they already knew. “We chose three keywords for the design: rope, mountains and luck.”

Over a two-week period, the team engaged in meticulous work, dipping the fabric into a 1,500-liter container — their largest dyeing vat — around 15 times. But Kaji doesn’t call himself a creative, and seems embarrassed when I tell him that I consider him an artisan. “Artisans work for years and years,” he argues, “but our products are relatively new.” Taking into account that his life is essentially devoted to the growing and dyeing of indigo, it’s hard to agree with his humble statement.

Photos by Kyoko Nishimoto, BUAISOU

Pride of Place

Arriving at the Arc’teryx Tokyo Creation Center opening, we find a queue out the door. Kaji balks and puts on a mask, a dark gray that complements his clothes. Upon entry, we’re given a free gift: a bandana in the shade of deep blue, made by Buaisou. The Arc’teryx crew had been so pleased with the artwork that they’d commissioned an additional piece to be given to guests at the opening event. The bandanas are hot property.

Attending the event with Kaji and Nishimoto, it’s clear just how much the work that they’ve done is admired by the people involved. It’s also evident that Kaji is a perfectionist, with incredibly high standards for himself. On the second floor of the complex is a dyed wooden stool — also dyed by Buaisou. We then head to a room in the corner, its doorway flanked with Japanese noren curtains in the company’s familiar blue. Kaji examines the noren. “It doesn’t fall how I’d envisioned,” he says, seeming disappointed. The curtains look great to me.

Photo by Brad Holdgrafer

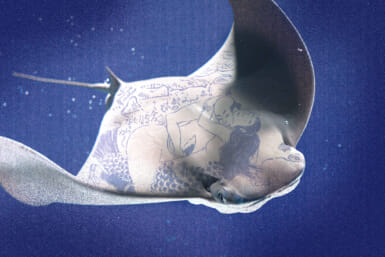

We move downstairs to the ground floor, though Kaji is stopped every few seconds by people wanting to congratulate him. Finally we arrive at his work, in pride of place across the gray concrete wall. The thick, majestic rope design flows across its surface, crossing the piece diagonally as it builds to a mountain from lower left to upper right corner, twisting and weaving, gleaming like a ray of light against dark navy blue, with a miniscule Arc’teryx logo in the lower left corner. Up close, it’s possible to fully appreciate the fine work and craftsmanship that has gone into its creation. Each fiber of the rope is delicately marked out on the cloth, the slight gradation from bottom to top, giving the piece unexpected depth.

Kaji may not think of himself as an artisan, but he’s more than your average indigo dyer. And, semantics aside, it’s undeniable that he has an artisan’s dedication to the craft. After checking out the piece, the Buaisou team retires from the event early. “I’m on the first flight tomorrow,” Kaji explains. “It’s seed-planting day.”

Photos by Kyoko Nishimoto, BUAISOU

To learn more about Buaisou, please visit their website.